Double Loader Semi Automatic Capsule Filling Machine

Double Loader Semi Automatic Capsule Filling Machines

Double Loader Semi Automatic Capsule Filling Machine fabricated for precision manufacturing requirements of advanced pharmaceutical procedures. The semi automatic capsule filling machine provides higher degree of automation with simple function. Capsule Filler is suitable to fill capsules of different sizes with fill option of powder, granules & pellets. This semi automatic capsule filling machine is made as per cGMP compliance and provide output of up to 45,000 capsules per hour depending on capsule size and operator proficiency.

We also provide in our range capsule line equipments naming Capsule Conveying System, Dust Extractor, Capsule Polishing Machine, Damage Capsule Sorter and Empty Capsule Ejector to make complete Semi Automatic Capsule Filling Line.

Machine Synonyms:

Semi-automatic Capsule Filling Machine, Semi-Automatic Capsule Filler, Double Loader Capsule Filling Machine

Technical Specification of Double Loader Semi Automatic Capsule Filling Machines:

Application:

Filling Capsules with powder, pellets and granules

Usage:

Pharmaceutical, Health Supplement, Nutritional, Biotech, Food Product & Cosmetics

Suitability:

Hard Gelatine, HPMC & Vegetarian Capsules in 00, 0, 1, 2, 3, 4 & 5 sizes

Version:

Double Loader

Double Loader Semi-Automatic Capsule Filling Machine, ASCF – 45

Working Platform:

Back View & Connections:

Option of attaching Capsule Polishing & Sorting Line for online operations

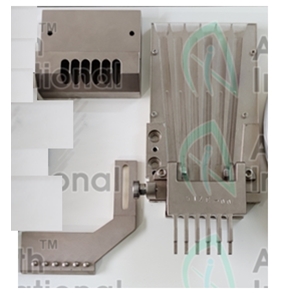

Different designs of Auger Blades provided with machine for different bulk density material

Change Parts Set Includes:

Loading Ring

Pin Plate Assembly

Loader Change Parts

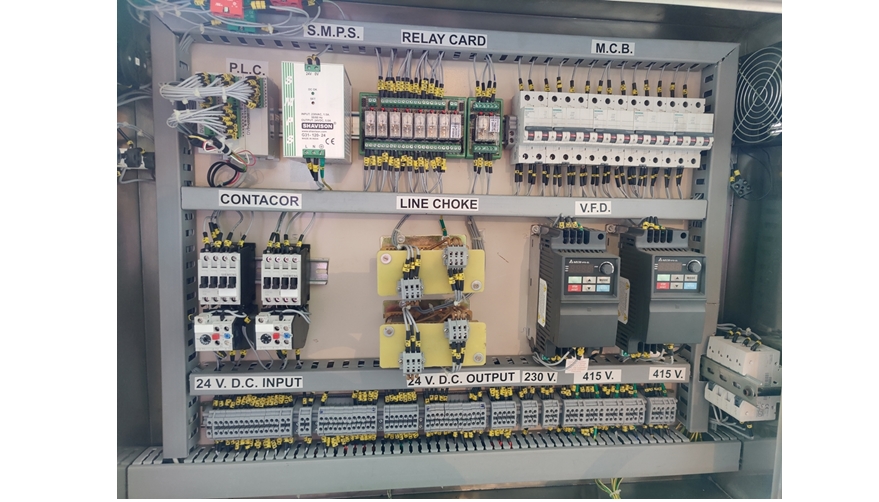

PLC & HMI Based Automation:

Process Operation:

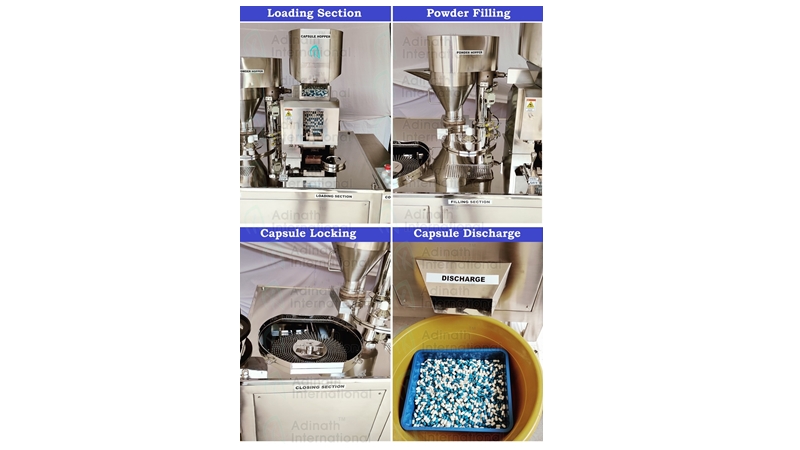

The Semi Automatic Capsule Filler is easy to set up. One hopper holds all of the capsules. Any size from 00 to 5 can be accommodated in this hopper. Following that, the powders are placed into a separate hopper. This is a corkscrew-driven hopper that ensures a consistent fill in each capsule. The vacuum sucker is then used by the operator to sift and feed the capsules into the loading rings one by one. Loading Rings are available in sizes ranging from 00 to 5. The vacuum is then used to separate the capsules by the operator.

The loading rings are pulled apart once the capsules have been separated to release only the bottom section. This bottom half is then inserted into the machine's filling section. The operator can turn on the filling once the loading rings have been inserted in this area of the machine. As a result, the filler slides across the capsules, rotating the capsules beneath it. The powder is then equally forced down into the capsules by the corkscrew. This guarantees that all capsules are the same size and weight. The two loading rings are then reassembled and inserted into the capsule filling machine's sealing portion. The operator closes the guard and utilises air pressure to seal the capsules after they are aligned. After that, the capsules are removed from the loading ring.

This machine also has a capsule cleaning option once the capsules have been created. The capsule polishing machine features a set of corkscrew brush bristles inside and employs a dust extractor unit connected to it. This dust extractor system uses a vacuum to de-dust the capsules, leaving them with a high-quality, professional finish.

Salient Features of Semi-Automatic Capsule Filling Machine:

- Higher production output up to 45,000 capsules per hour.

- Double Empty Capsule Loader stations for faster output

- Online capsule polishing & sorting attaachment.

- No operator requires for capsule polishing & sorting.

- Automatic empty capsule separation after Loading – No need to turn by hand.

- No extra power consumption.

- No need to store filled capsule for polishing.

- Loader gets disengaged automatically after one complete rotation of loading ring.

- PLC controlled digital display of all operations.

- Auger with four speeds to fill different type of powders & pellets.

- Modified design of drug hopper reduces time for dismantling and unloading of powder.

- Auto-drug hopper in-feed mechanism reduces weight variations & improves productivity.

- Automatic declutching of loader when the loading rings are full minimizes operator attention and ensures optimum production.

- Infinitely variable filling table speed ensures dosage accuracy.

- Automatically drug hopper in-feed mechanism eliminates weight variation, reduces operator fatigue and enhances productivity.

- A choice of four augur speeds enables the machine to handle a wide variety of powder from highly hygroscopic to the very free-flowing.

- Automatic Capsule Closing System ensures faster, safer closure and ejection of filled capsules.

- Automation of Loading Station - This eliminates the need for continuous operator attention as solid-state control circuitry provides automatic stoppage of the loading table after completion of one cycle, each of 60 strokes.

- Automation of Filling Station - This, again, is a revolutionary feature that eliminates the need for continuous operator attention. Motorized swing-in and swing-back of the drug hopper after one filling cycle results in reduced operator fatigue.

- Pneumatic Closing Station - This utilizes an electronic sensor which activates a pneumatic cylinder to carry out the closing operation resulting in ease of operation and reduced operator fatigue.

- Vertical Closing - Vertical closing of filled capsules reduces reject rates and powder spillage. This is critical for pellet filling. This is achieved by having two speeds for auger and nine speeds for filling table operation.

- Modular type hopper provides easy and fast dismantling for cleaning. Change-over times between batches are reduced.

- Filled Capsule Output Capacity can be increased using our ring loading station. This allows existing SA-9 installations to be upgraded for extra production.

- Large De-dusting Screen on the ejection chute provides for easy separation of powder adhering to filled capsules.

Technical Specification for Double Loader Semi Automatic Capsule Filling Machines:

| Sr. No. | Model | ASCF - 45 |

|---|---|---|

| 1 | Production Output /hr. | Up to 45,000 capsules |

| 2 | M.O.C. of Loading Ring M.O. C. of contact parts |

Magnesium Alloy Stainless Steel 316 |

| 3 | Number of Ring | Double |

| 4 | Number of Holes | Size 00: 480 Size 0: 600 Size 1, 2, 3, 4 & 5: 720 |

| 5 | Power Supply | 3 Phase, 415 Volts, 50 Hertz |

| 6 | Compressed Air | 8 CFM |

| 7 | Machine Dimensions Length (In mm) Width (In mm) Height (In mm) |

2650 1250 1800 |

| 8 | Net Weight in Kgs. | 1250 |